RFID what it is?

It is a unique and automatic identification technology, based on electro-magnetic waves that propagate in the air and allow the remote identification of living beings and objects, both moving and static. The real meaning of the letters “RFID” corresponds to the English acronym for Radio Frequency IDentification.

In practice, it is used to identify any product, giving it a unique identity on an electronic level. In this way, RFID acts as a bridge between the physical world and the digital world, giving a unique identity to any object or living being that enables the interconnection between objects, people and various services: in practice Internet of Things (IoT)

TAG: What is it. - RFID labels.

An RFID tag is a simple self-identification tag that has a microchip and antenna.

This electronic label (TAG) has the function of storing and transmitting data without the need for physical contact.

It also allows you to unambiguously follow every single product, since the RFID TAG is unique and unrepeatable.

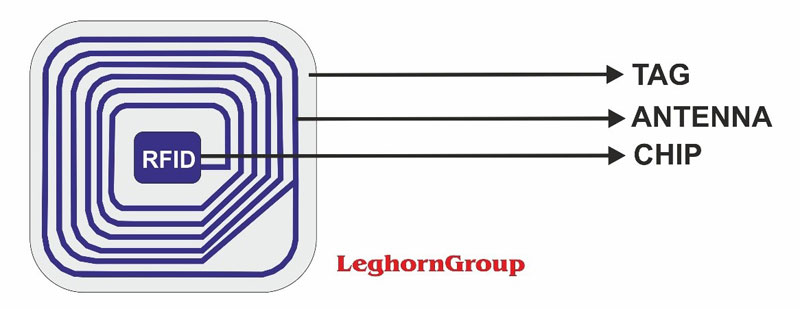

Basic components of an RFID tag are:

- Microchip

- This component contains the label-specific data.

- It can store information such as unique codes, product handling, production data, storage point.

- Antenna

- The antenna wirelessly transmits data contained in the microchip.

- It allows two-way communication, when activated by a radio frequency signal emitted by an RFID reader.

- Support

- Normally it is a label made of adhesive paper, or plastic.

Types of TAGs:

Passive TAGS

- They have no energy of their own

- Short reading distance

- Inability to integrate auxiliary

sensors

LOW COST TAG

Semi-passive TAGS

- They are helped to “awaken” thanks to their own

energy - Long reading distance

- Can integrate auxiliary sensors

MEDIUM COST

Active TAGS

- They have their own energy

- Long reading distance

- Can integrate auxiliary

sensors

HIGH COST

Is RFID the same as NFC?

The answer is NO!

NFC is a subset of RFID technology. In fact, it is limited compared to RFID.

NFC works at a distance of up to 10 cm.

Above this distance the NFC is unable to communicate with the reader.

NFC allows two-way communication between the reader and the NFC TAG.

How Passive RFID Works

Identification is done using an antenna to read a chip (called tag, or transponder) that has been applied to the object (or person or vehicle) to be identified. The tag contains a certain amount of information about the object on which it is applied (such as the code, the date of manufacture, the manufacturer), which can be static, or change over time.

The tag does not need power sources (electricity) to work: when it is “illuminated” by the magnetic field of the antenna to which it is exposed, the tag is in fact able to accumulate the little energy it needs to transmit, to short distance, the information it contains. This type of tag is called “passive.”

When it enters the field of action of a reader (from a few centimeters to a few meters) the tag is “woken up” by the ELECTROMAGNETIC FIELD generated by the reader and responds by “reflecting”, modulated, the signal.

The modulated response signal is then received by the reader which decodes it. This type of tag, called passive, is the most popular on the market thanks above all to the price that makes it usable in many applications.

ACTIVE RFID

How it works technically

The Telepass is an example of an active RFID transponder application

If, on the other hand, it is necessary to transmit over a long distance, a higher power is required and the tag must be powered by an electricity source, such as a battery.

In the latter case, the tag is called “active”.

There are many sectors in which RFID technology can be applied.

Tags are spreading a lot in the sectors of industrial production, logistics and clothing, but also in healthcare, public administrations, access control, etc.

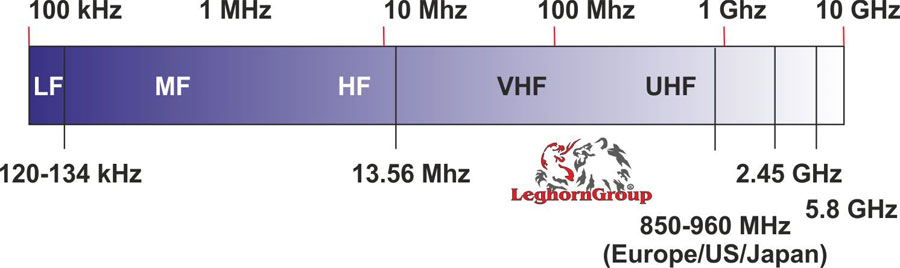

What are the frequencies used in RFID?

RFID systems use various frequencies, which can be classified as:

– low frequencies (LF, between 125 and 134 kHz)

– high frequencies (HF, around 13 MHz)

– very high frequencies (UHF, between 860 and 960 MHz)

– microwave (over 2.45 GHz)

In general, as the frequency increases, the reading distance and the amount of information that can be transferred in a unit of time increase, the ability to withstand operating conditions and costs decrease. Low-frequency (LF) tags use little power, are capable of passing through non-metallic materials and liquids, but the signal for reading does not exceed 30-40 centimeters.

High-frequency (HF) tags work best with metal objects and can cover a distance of about one meter.

Ultra-high frequencies (UHF) offer wider read ranges and allow data to be transferred quickly, but do not pass through materials easily.

Solutions with 2.45 GHz tags are used in telepasses and similar.